-

Home

-

Products

-

News

-

About Us

-

Support center

-

Blog

-

Contact Us

inquiry

Leave Your Message

In the ever-evolving world of electronics manufacturing, choosing the right equipment is crucial. A reliable Pick And Place Machine PCB can significantly enhance production efficiency. These machines automate the placement of components on printed circuit boards, reducing human error and saving time.

However, selecting the best option can be daunting. Many machines vary in features, speed, and price. It's easy to feel overwhelmed by the choices available. Businesses need to consider their specific requirements and budget. Not all machines may suit every operation.

Investing in a Pick And Place Machine PCB may seem straightforward, but many factors must be evaluated. Some machines offer high precision but come at a premium. Others are more cost-effective but may lack advanced features. Finding the right balance is essential for optimizing manufacturing processes. Thoughtful reflection can lead to better decisions that align with business goals.

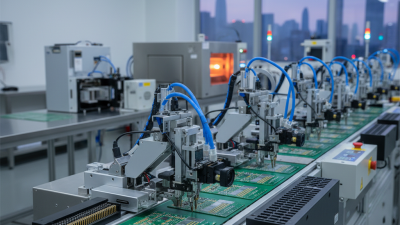

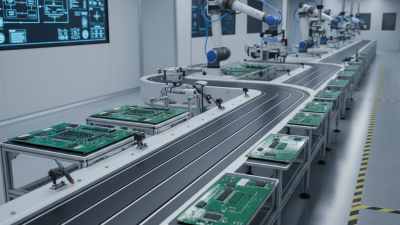

Pick and place machines are vital in PCB assembly. They automate component placement, increasing efficiency and accuracy. Understanding their functionality is essential for businesses. These machines use pick-up heads to grasp components and position them precisely on PCBs. A vision system often guides this process, ensuring alignment with design specifications.

However, choosing the right machine is challenging. There are various options available with different features. Some machines handle larger components, while others focus on speed. It's easy to get overwhelmed by technical jargon. Not all solutions fit every production need. Businesses must assess their specific requirements first.

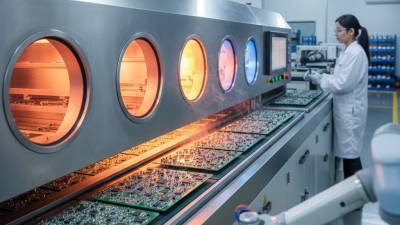

Maintenance is crucial for pick and place reliability. Ensuring proper calibration can prevent costly errors. Regular checks help avoid malfunctions. It’s also essential to train operators effectively. Misunderstandings can lead to inefficiencies. Reflecting on these aspects helps in making better decisions. The goal is to find a balance between cost and performance for optimal results.

| Model | Placement Speed (PPH) | Max PCB Size (mm) | Number of Heads | Price Range ($) |

|---|---|---|---|---|

| Model A | 6000 | 460 x 460 | 4 | 15,000 - 20,000 |

| Model B | 3500 | 500 x 500 | 2 | 10,000 - 12,000 |

| Model C | 4500 | 400 x 400 | 3 | 8,000 - 10,000 |

| Model D | 7000 | 600 x 600 | 6 | 25,000 - 30,000 |

| Model E | 5000 | 450 x 450 | 5 | 12,000 - 18,000 |

When choosing a PCB pick and place machine, several key features should be prioritized. One crucial aspect is placement accuracy. Machines that offer high precision ensure components are placed correctly. This reduces the risk of defects during soldering. Automation also plays a vital role. A fully automated system can enhance productivity and minimize human errors. A balance between speed and accuracy is essential.

Another vital feature to look for is the machine’s capacity and flexibility. A good pick and place machine can handle a variety of components. This includes different sizes and types, which helps in adapting to changeable production needs. Additionally, software capabilities should be considered. User-friendly interfaces simplify operation and programming. Intuitive software can decrease setup time significantly.

Consider also the support and maintenance services that come with the machine. Regular upkeep is necessary for optimal performance. However, not every provider meets this need adequately. It's important to reflect on whether the machine will fit your long-term production goals. Ultimately, choosing the right machine requires careful thought and a clear understanding of your unique operational demands.

When selecting a pick and place machine for PCB assembly, various manufacturers offer distinct options. The right choice depends on your specific business needs. Some machines focus on speed, while others excel in precision. It's essential to align these features with your production goals.

Tips: Evaluate your production volume. If you have high demand, faster machines may seem appealing. However, speed shouldn't compromise quality. Look for balance. Some manufacturers emphasize user-friendly interfaces. This can enhance your team's efficiency. Simple controls can also reduce training time.

Assess the machines' adaptability. Different projects require different components. A flexible machine can handle various sizes and types. But some machines may struggle with uncommon parts. This limitation could slow down your workflow. Ensure the machine you choose is well-reviewed for reliability and maintenance support. Regular upkeep is vital for smooth operations.

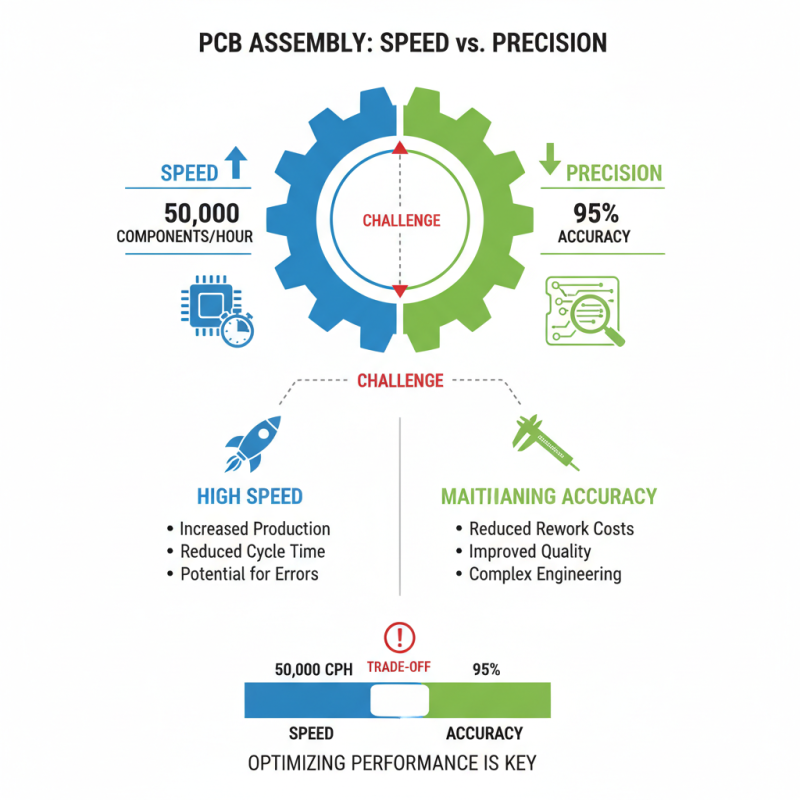

The following chart illustrates the production capacity (in units per hour) and accuracy (% placement accuracy) of various types of pick and place machines commonly used in PCB assembly. This data helps businesses identify the most suitable options based on their specific production needs.

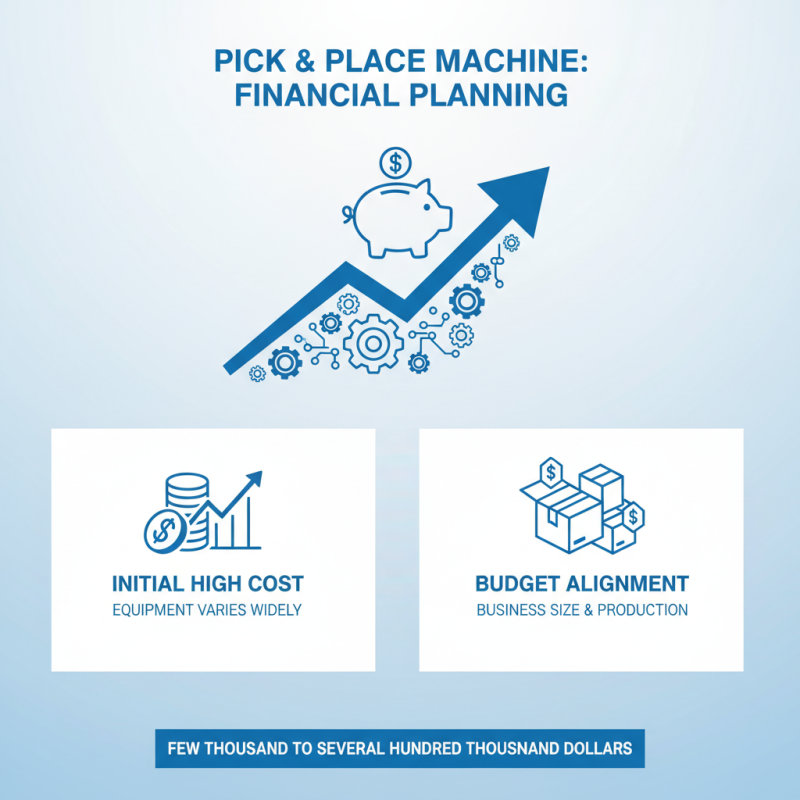

Investing in a pick and place machine requires careful financial planning. The initial cost can be high. Equipment choices vary widely and impact your budget significantly. You might find machines ranging from a few thousand to several hundred thousand dollars. It’s crucial to establish a budget that aligns with your business size and production needs.

Consider maintenance costs as well. Ongoing maintenance can add up. Regular service ensures machines run smoothly, but also comes with fees. Training staff adds another layer to your budget. Investing in a skilled workforce is essential for maximizing the machine's potential. Evaluate the trade-offs between cheaper machines and more robust options.

Additionally, think about the long-term value. Cheaper machines may save costs initially but may lack durability. This could lead to increased downtime and repair costs later. Reflect on your production goals and the potential return on investment. Finding the right balance between cost and quality is critical. Aim for a machine that meets your needs without compromising your financial stability.

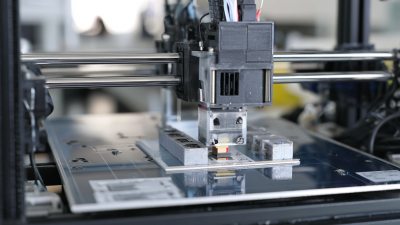

The performance of pick and place machines is crucial for PCB assembly. Speed plays a vital role in production. A recent study indicates that machines can achieve speeds of up to 50,000 components per hour. However, reaching such speeds often sacrifices precision. Maintaining accuracy at high speeds remains a challenge for many manufacturers. Some machines report accuracy rates of around 95%, but this can lead to increased rework costs.

Precision is not just about placement but also alignment. Misalignment can result in defective boards. Industry data shows that a mere 0.1mm error can lead to significant failure rates in high-density assemblies. Many businesses find themselves grappling with this issue. They may choose a faster machine, only to face higher returns.

Reliability is another critical factor. Machines face wear and tear over time. Regular maintenance is essential to ensure consistent performance. Reports suggest that companies with proactive maintenance schedules reduce downtime by 40%. Still, many wait until problems arise, causing production delays. Investing in more reliable options often leads to higher upfront costs but can save money long-term. Balancing these factors is key for a successful PCB assembly operation.